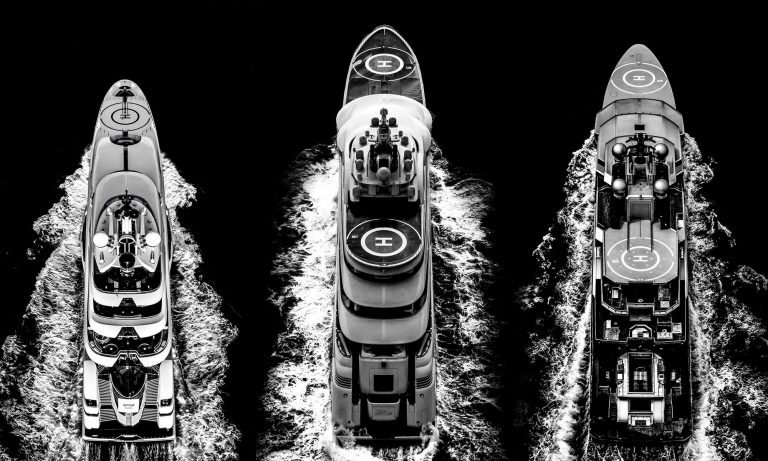

Today, Hythe Group specialise in the provision of premium design and engineering services. The Group operates globally within a variety of industries such as building, commercial, marine as well as the storage and distribution sector. But where did Hythe Group begin?

A little history

The original business, Hythe Marine Services (HMS), are renowned worldwide for their work on bespoke design and engineering services. As HMS developed a strong reputation within the marine sector, demand for their design and engineering services started to diversify beyond that of the marine market.

At this time the company’s sole focus was not on growth, or being the biggest company within the industry, speak with Hythe Group Director Josh Mathias and he will tell you it’s all about being the best at what you do, that reputation for delivering unrivaled quality and service is far more valuable than purely chasing market domination.

Having said that, in 2016 a highly motivated team within HMS pitched the idea of separating the company into two entities. One side would continue operating within the marine sector and the other would focus wholly on the building industry to meet growing demand. They saw a requirement to take on small prefabrication and installation packages for larger companies, who held a major part of contracts. The demand was clear, these larger companies were over stretched and needed a reliable, flexible and motivated team to take care of the problem. Josh Mathias commented that, “funnily enough this attitude towards work was how Hythe Marine Services was built and is what continues to ensure its growth today.”

Anyone who’s done it will tell you that the thought of starting a new business is daunting. However when it became clear there was an opportunity for slow, controlled growth, and high demand for quality labour within the commercial sector, expansion seemed to be a good and progressive option. And so in 2016, the team took the leap and Hythe Pipe Services was born, which later got rebranded as Hythe Building Services in 2019.

“It’s largely because of that team that the idea became a reality. Today the foundations have become even stronger by bringing in like minded people to help drive the company in the correct direction at a controllable rate.” Josh Mathias | Director |Hythe Group

Today Hythe Building Services (HBS) specialise in bespoke pipework, welding, fabrication and design services within the industrial, commercial and public sectors. For HBS to succeed, in this new and extremely competitive market, the team focused predominantly on controlled growth and the maintenance of Hythe Group’s reputation with solid client relationships and outstanding project deliverance.

Three years later, in 2019, Hythe HOSMU was formed. This division within Hythe Group is a concept driven manufacturing business capable of designing, manufacturing and implementing consolidated and organised mass storage and distribution solutions. The team specialise in providing bespoke solutions to unique storage and distribution challenges, access limitations and/or functional hurdles.

Hythe HOSMU was developed in partnership with Our Soles Ltd. and Heathrow Airport, to provide bespoke storage and distribution solutions to Heathrow’s winter resilience team. Although this is the youngest company within Hythe Group, HOSMU will soon begin to take on larger projects of mass-produced and bespoke items, using its knowledge from the marine fabrication sector to fast track its quality and set up.

“Hythe Group were the perfect team to choose for the Heathrow project. I had seen how diverse their skills in metal fabrication and engineering really were, skills that were essential for the bespoke nature of the Heathrow Airport project.” Neil Robinson | Managing Director | Our Soles Ltd.

After the creation of Hythe HOSMU Josh decided it was time to group the companies together and link them all under one umbrella. The overarching Hythe Group brand now allows for the promotion of each company’s diverse skill set through one single platform.

The role of the team

A unique advantage for Hythe Group businesses is the ability to create brand new companies using existing team members. Hythe Marine employee capabilities are recognised globally for their quality service, high standards, unique skills and attention to detail. These characteristics have carried through to the newer companies and employees.

Many team members have worked together for decades, harking back to when HMS was under previous titles Avrotech Design and Mathon Engineering. These long term employees of Hythe Group are known by name with industry-leading organisations, such as the Royal Navy, Babcock, BAE systems and the Ministry of Defence.

The small team who came up with the idea to split HMS into marine and building divisions are a great example of the Hythe Group mentality. It was because of their knowledge and dedication that the idea became a reality. Since then, the foundations have become even stronger by bringing in like-minded people to help drive the company in the correct direction.

We asked Josh Mathias about the team dynamic at Hythe Group: “The entire group at all levels enjoy improving themselves. The senior workforce is happy to pass on their knowledge to our apprentices and it’s great to watch them support the younger generation by passing on their knowledge within specific trades. In years to come, these apprentices are going to be highly skilled in multiple disciplines, making them the future must-haves hybrid traders of the industry.”

Group diversity

The staff turnover at Hythe Group is almost non-existent. Because of this, there are ever-growing amounts of in-house knowledge to continue the overall goal of upskilling and developing the workforce throughout the group.

Creating Hythe Group has made the company extremely versatile in applying their core skill sets. The workforce are able to comfortably move around to meet demand due to their wide-ranging experience. Despite being standalone companies, Hythe Group’s integrated teams ensure they are able to assist each other in periods of high or low demand.

Team members are used to following incredibly strict policies and procedures. As a result the group is renowned for their ability to complete demanding turnkey projects in what are usually very short time scales.

What comes next?

An inevitable result of carrying out quality work and building strong relationships is an increase in demand. Hythe Group predicts the continued natural growth of each business for the coming years. This will be managed by selecting the right companies to work with, by taking on turnkey projects and supporting a growing workforce.

Hythe Group’s immediate focus is the development of each business within the group, working to solidify their foundations, maintain the Hythe brand reputation and grow at a controllable rate. But most importantly, Hythe Group will ensure both the workforce and their clients are being looked after.

To discuss how Hythe Group can assist with your next project?